Tom

Beta Return

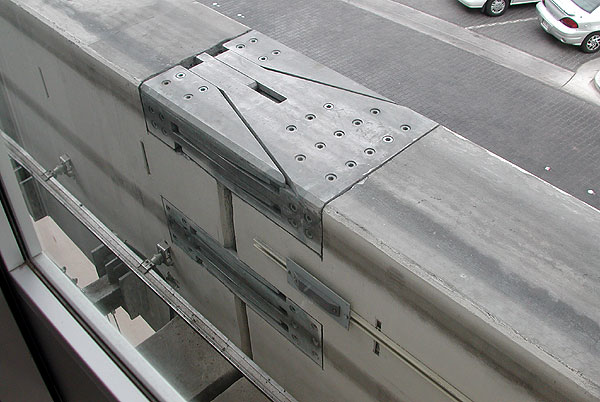

Picture this gap, except bigger

Interestingly enough the LV Monorail beam has improved the design dramatically to deal with the extreme temperatures that are present there.

Excellent, thanks for the photos.

The LV design is significantly better. The splice plate on top virtually eliminates the chance of a void under the tires.

This must have been one of the minor modificaitons they made to the WDW beam design, since the LV beams were made using the exact same design. I had the opportunity to visit the plat of desert where they were casting them for the original run.

Looks like a little concrete cutting and they could drill and epoxy some anchors into the top of those splice points and install the plates that LV installed. It could literally be done overnight....especially with the early shutdown of those lines.