s8film40

Well-Known Member

Here's some beam info from the manufacturer for anyone interested.

http://www.concretetech.com/project%20reports/disneyworld.htm

http://www.concretetech.com/project%20reports/disneyworld.htm

Thanks for the link.Here's some beam info from the manufacturer for anyone interested.

http://www.concretetech.com/project reports/disneyworld.htm

Yes. The force will tend to follow around the outside or skin of a member. The material at the center of a solid core only gets about 10% of the actual load so from a weight to strength perspective the material is largely waisted.Is this because the energy of weight goes around the the outside shape (which would be a circle in this case, or a square/rectangle of the monorail beam) instead of through it? Kind of like how the energy goes down and then outward on an arch?

I love science.Yes. The force will tend to follow around the outside or skin of a member. The material at the center of a solid core only gets about 10% of the actual load so from a weight to strength perspective the material is largely waisted.

Concrete is not my specialty and unfortunately I do not have a cross section of one of the monorail beams but I to would think that there has to be be either rebar or pre-tensioned cables in the beams. Concrete with only a styrofoam core would eventually shatter under constant loading and unloading.Okay, Yoda, some of that went over my head because my brain sees all that stuff and says, "Um..NO!". LOL! So the core is basically a poly-styrene. Got that. I get that the core doesn't need to be the strongest part. Got that. What I want to know is would there still need to be any amount of rebar in the concrete to give flex without crumble or does the core have the ability to perform this function? I would think not but I'm not so knowledgeable about this stuff. It's hard for my brain to accept some things (mostly math, physics, and science related) but that doesn't change the fact that I'm just plain curious. :shrug::hammer:

Just an FYI our favorite Bad Astronomer Phil Plait just got his own show on Discovery called Bad Universe.:sohappy: http://blogs.discovermagazine.com/badastronomy/2010/07/23/my-sooper-sekrit-project-revealed/I love science.

Here's some beam info from the manufacturer for anyone interested.

http://www.concretetech.com/project%20reports/disneyworld.htm

Concrete is not my specialty and unfortunately I do not have a cross section of one of the monorail beams but I to would think that there has to be be either rebar or pre-tensioned cables in the beams. Concrete with only a styrofoam core would eventually shatter under constant loading and unloading.

I would bet that house it does have rebar... just not the amount if it were solid.Concrete is not my specialty and unfortunately I do not have a cross section of one of the monorail beams but I to would think that there has to be be either rebar or pre-tensioned cables in the beams. Concrete with only a styrofoam core would eventually shatter under constant loading and unloading.

Just an FYI our favorite Bad Astronomer Phil Plait just got his own show on Discovery called Bad Universe.:sohappy: http://blogs.discovermagazine.com/badastronomy/2010/07/23/my-sooper-sekrit-project-revealed/

From my understanding the cores of the beams were made of polystyrene (Styrofoam). The styrofoam itself would not add any strength to the structure. What it would do is allow for a virtually weightless void or series of voids to exist inside a monorail thereby increasing the beams strength to material weight ratio much in the same way that a hollow pipe is stronger by weight than a solid one is.

Concrete is not my specialty and unfortunately I do not have a cross section of one of the monorail beams but I to would think that there has to be be either rebar or pre-tensioned cables in the beams. Concrete with only a styrofoam core would eventually shatter under constant loading and unloading.

This is much cooler then the use of the foam and makes so much sense. Did I mention that I love science.Exactly correct (as usual) on both accounts. I had the extreme pleasure of witnessing the construction of an exact replica of the WDW monorail beams when I was in Vegas for a Construction Convention (AGC) during college (circa 2000).

Since the vegas monorail system was actually using WDW's old trains when it first opened, they used WDW's exact beam design for the initial part of the route. We got a tour of the giant area of desert where they were making the beams, and they were actually pouring one while we were standing there.

The "magic composite" inside the beams is literally Styrofoam. They build up formwork the size and shape of the beam, then drop in a MASSIVE rebar cage that wraps around the perimeter of the beam, for the entire length of it. It's so dense that the aggregate in the concrete has to be extremely small so that a piece of gravel doesn't get stuck in the rebar, causing a void in the concrete.

They put giant blocks of foam inside the rebar cage, and slip flexible plastic tubes through the foam from one end to the other. They run steel cables through these sleeves and pre-tension them.

To the layperson, this means they pull really, really hard on the ends of the cables so that they're as taught as possible while they pour. Once the concrete has cured around them, they weld the ends of the cables into end-plates that embed into the ends of the beam. Since the cables are then in a state of stress forever, they transfer their tension to the beam, giving it more strength.

So, you essentially end up with a concrete and rebar shell around a foam core with pre-tensions cables running the length. They beams are therefore much lighter than they would be with solid concrete, and FAR stronger, which allows them to span the great distances that they do.

EDIT: I'll see if I can find any photos in my old albums from that tour. Those were still the days of "film" cameras, so if I have anything, I'll have to scan them in.

To the layperson, this means they pull really, really hard on the ends of the cables so that they're as taught as possible while they pour. Once the concrete has cured around them, they weld the ends of the cables into end-plates that embed into the ends of the beam. Since the cables are then in a state of stress forever, they transfer their tension to the beam, giving it more strength.

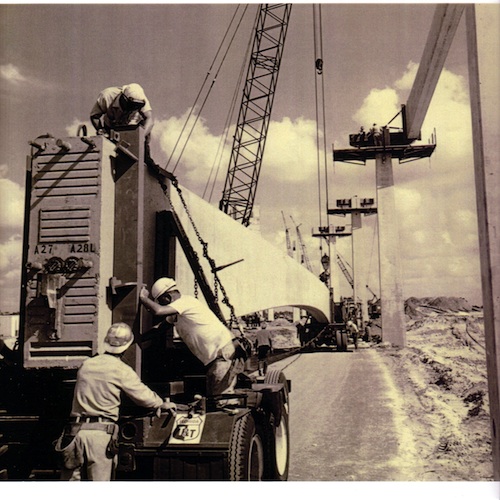

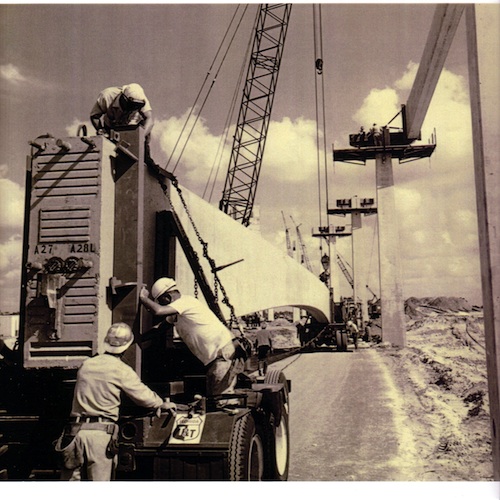

Here's an old photo of the WDW beams that illustrates what you are describing.

Original ALWEG beam design used a hollow core in all their projects and the original loops at WDW. The EPCOT loop is noted is filled with styrofoam. Below is a picture of each type.

(MK loops built to classic ALWEG hollow standard)

(LVM Track construction same as EPCOT line)

Thank you for the supplemental information. The first picture shows an "I-beam" shape, but the concept of the hollow core is probably right (I'm not even sure they had styrofoam in 1970). However, the fact that there are no tension cables shown is sort of scary.

EDIT: There still must have been something on the inside of the Alweg beam for the actual pour, which is probably the only reason they put foam inside them now - to keep the concrete from filling that area. It doesn't actually do anything structurally. They must have pulled out their inner core on the original beams for MK (as seen in the first photo).

The second photo (via link) looks very similar to what I saw in Vegas. I was out of order in my description - they did the foam and rebar first, then built the concrete formwork around it all.

The 1st photo is from the ALWEG site of either the Seattle or Italy Expo beam. Your right about the rebar it has to be hidden inside because this is probably a display beam or end on a spur.

The 2nd photo is Vegas (ding, ding 2 points!):lol:

Register on WDWMAGIC. This sidebar will go away, and you'll see fewer ads.