Sounds like you probably know more about this than I do. My thought process was that you’d be at disadvantage starting with a 3D printed mold as the base and have to need someone very talented to doctor it up and bring it up to par. For example the wrought iron work in NOS. Can you achieve that level of quality/ authenticity with this method? Would they even use this for something like that?

If you were 3D printing to make a mold, you could absolutely go

WAY more detailed than necessary for something like that. 3D printing is more commonly used for rapid prototying or one-off projects but there are lots of people out there who use it for creating the positive for a traditionally made mold that could then be used to create things either in bulk or with the intention of making out of sturdier materials like high melting temp metals.

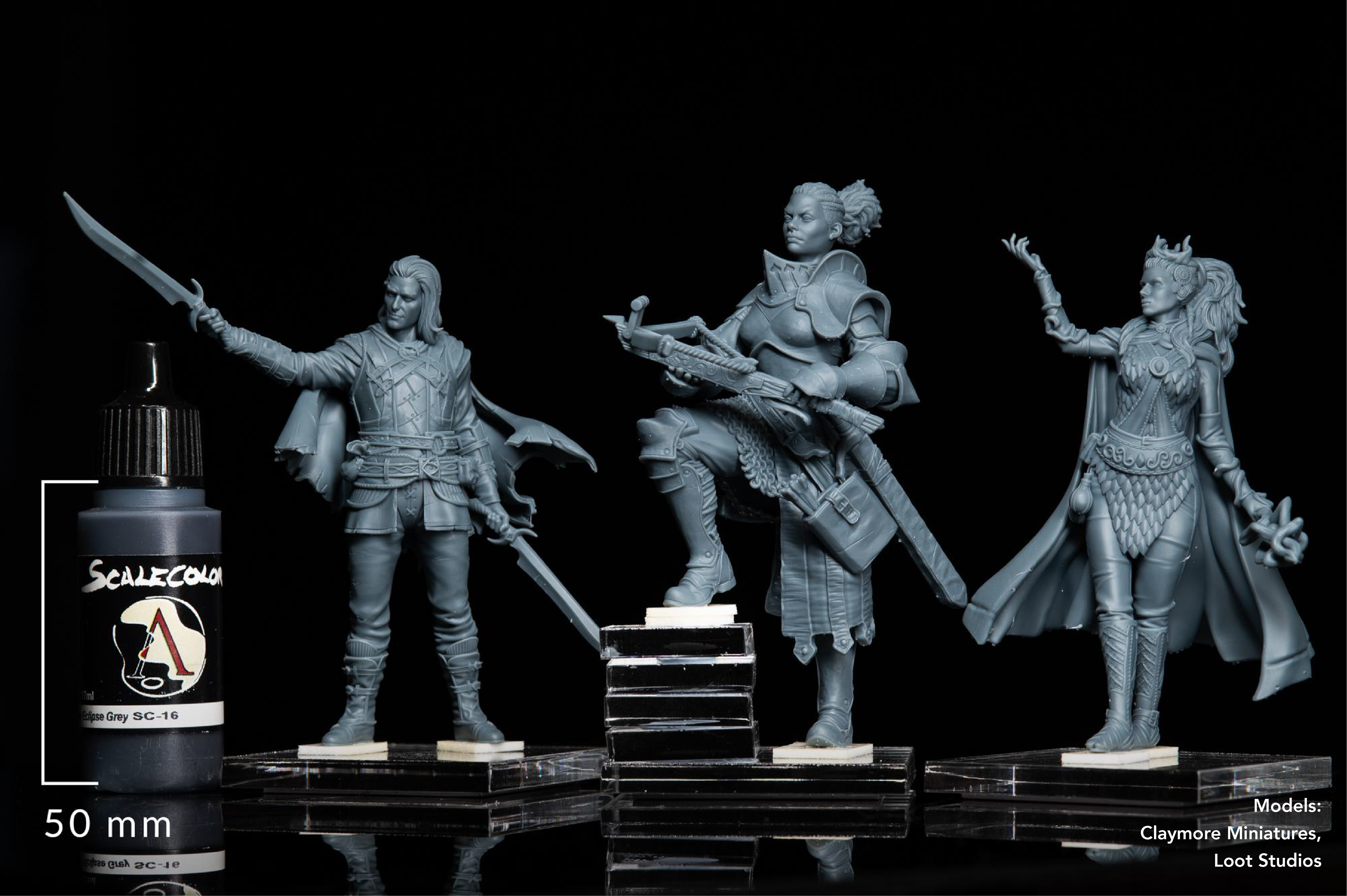

Just to give you an idea, the two most common methods at the consumer level are FDM and Resin - both of these you can achieve the quality in this video with off-the-shelf hardware that'll set you back less than $500.

Larger sized machines with accuracy cost more and there are other methods that work with powders and lasers that are considerably more expensive but also even more detailed, too. These would be machines designed and priced more for industrial use which a company like the one in the article is more likely to be using.

... but you can get pretty remarkable results with a little effort from a table in your garage, too these days.

When you use this as a base to build off of, you can do even more if you really want to - glob on some clay to a section, blend and carve it by hand if you really need hand detail, for instance. It's still a lot easier than starting the whole project that way but the detail of a decent resin printer and even the better FDM printers can be appropriate for making fine collectable miniatures so that shouldn't be necessary in most cases unless you are working with shapes that are challenging for some forms of 3D printing where gravity or pull forces come into play but even then, breaking the object into parts for assembly, similar to how the classic

Hummel figurines are made would still be an option.

EDIT - actually, his resin prints aren't all that detailed. You can go much finer than what he shows. For example:

and if you want to see what a talented artists can do with this tech and some post-processing work, check this guy out:

and this short just poped up in my youtube feed. It's a short so it's well, short to watch:

Obviously, that level of detail would look perfectly fine at a distance. For people concerned about seeing 3D printed objects up close, I'm curious how close most people here would think you'd have to get before a lack of detail would become a problem keeping in mind that something like this as a prop would go on to be hand painted, just as something done using a more traditional method would be.